The sake making process begins with rice polishing, which sake brewers call giving rice a polish. Carefully selected Miyamanishiki and Gohyakumangoku rice is polished, which removes the outer portion containing high amounts of protein and fat. Rice becomes more fragile as it is polished. The rotation speed of the rice polisher gradually decreases.Polishing rice for Daiginjo requires about 70 hours in order to polish to a ratio of 65%.

Once polishing is completed, the rice is washed to remove any remaining rice bran and other particles so that it absorbs water well. After polishing, rice becomes fragile and quickly absorbs water, requiring careful handling. Because the speed of water absorption varies with the temperature, humidity, and the condition of the water temperature, these processes are measured in seconds with a stopwatch. Once water absorption is completed, the rice is drained in preparation for the next step.

The rice containing water is steamed in a large vat and koshiki for about 40 to 60 minutes. The ideal condition of steamed rice is gaiko nainan, literally, hard outside and soft inside. Because the steamed condition of the rice greatly affects the post-process and sake quality, this procedure is carefully completed while checking the condition during the entire process. Once the rice is steamed, it is cooled to about 30℃ by spreading on a cloth.

Steamed rice is transferred to a special room used only for making koji, which is maintained at an elevated temperature around 35℃. After that, seed koji spores are sprinkled to make koji while adjusting the temperature and moisture content. Approximately 48 hours are required to make koji. During the koji making process, brewers use their hands to loosen the rice to prevent overheating and cover the rice with a cloth to prevent drying, which requires brewers to work continuously day and night.

Yeast, which bears fermentation, is made by combining koji, steamed rice and water. Also called a yeast starter, kobo making is a crucial procedure that forms the structure of sake making. This process requires strict temperature control and diligent checks of the conditions at every level. Sake brewers pay considerable attention at all times to encourage the propagation of yeast by stirring with a paddle.

Shubo is mixed together with koji, steamed rice, and water to make moromi. Using a traditional method that has been practiced since the Edo era, called three-stage preparation in which the moromi is prepared in three stages, the kobo and lactic acid in a moromi is allowed to propagate steadily and slowly. Under complete temperature control, the fermentation process is complete in about a month.

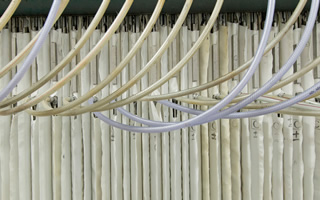

After fermentation, the moromi is transferred to a special room called funaba. The moromi is pressed to separate the sake from the sakekasu (lees) using air pressure. This procedure is called jōsō. As the percentage of the different components in the moromi are transferred to the sake depending on the pressure, this procedure is crucial in determining the level of freshness and boldness of the taste of the sake.

After jōsō, the sake is filtered to remove particles floating in the sake. After that, the sake is heated to a temperature of 65℃ to 67℃ for pasteurization, which is also called heat treatment; the sake is then stored in a tank for slow maturation over the course of the summer. On the other hand, there is a kind of sake that is not pasteurized, which results in a fresh flavor. Non-pasteurized sake is called namazake or namachozoshu, which is the raw stored sake.

This is the final blending step before shipment. As the flavor of sake varies from tank to tank, even with the same ingredients and process, a skilled craftsman tastes each sake to adjust the quality. The sake undergoes another heat treatment immediately before bottling. Finally, it is then bottled and labeled. This is how Funaotaki is delivered to your table.